Meter-Lab’s spectrometers have a high spectral resolution of 0.1 nm and undergo wavelength calibration procedures traceable to international standards. To maintain the spectrometer’s high resolution and wavelength measurement reliability, it is important that the optical alignment—once completed during wavelength calibration—remains stable despite the vibrations that can occur between shipment from Meter-Lab and installation at the customer’s site.

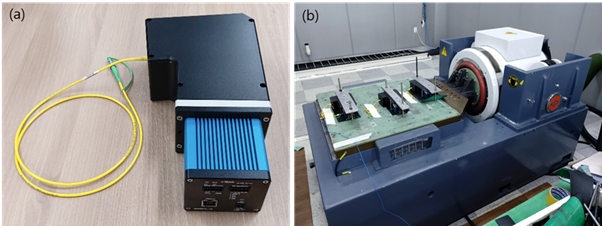

To apply vibration to the product, we commissioned a vibration test at the Korea Testing & Research Institute for Reliability (KTR). As shown in Figure 1, three s-Nova-1550 spectrometers were prepared and tested using a multi-environment vibration shaker. The vibration profile followed the vehicular transport vibration specification in the U.S. Army’s MIL-STD-810G standard.

Figure 1. (a) Meter-Lab s-Nova-1550 spectrometers, (b) vibration test setup

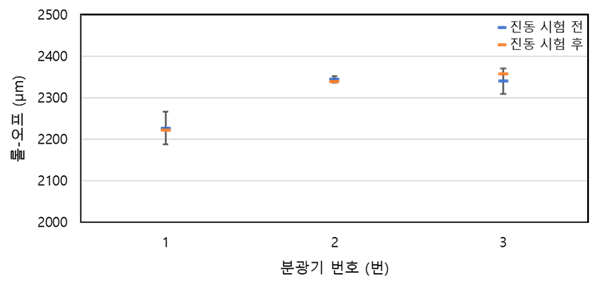

We evaluated vibration durability by comparing roll-off performance before and after the vibration test and by injecting five single-wavelength light signals into the spectrometer and comparing the pixel positions of the wavelength peaks in the spectra. First, roll-off performance is an indicator of how well a spectrometer can resolve high-frequency components; if the optical axis alignment inside the spectrometer is disturbed, roll-off performance will degrade. As shown in Figure 2, the difference in roll-off values before and after the vibration test was at most 18 μm, which lies within the standard deviation of three repeated pre-test measurements, indicating no change in performance.

Figure 2. Comparison of roll-off performance before and after the vibration test

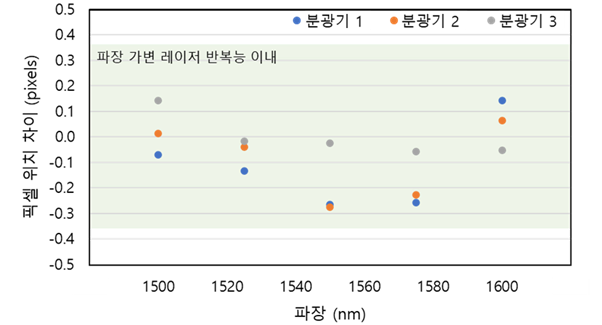

Next, we checked for pixel-position shifts by inputting five single-wavelength signals into the spectrometer. We used wavelengths of 1500 nm, 1525 nm, 1550 nm, 1575 nm, and 1600 nm, all within

the s-Nova-1550’s spectral range. The pixel-position comparison for these five wavelengths (Figure 3) showed a maximum shift of 0.28 pixels, corresponding to a wavelength change of 0.032 nm.

The tunable laser used as the light source has a wavelength repeatability of 0.042 nm, which corresponds to 0.36 pixels. Because the pixel shifts for all wavelengths remained within the tunable

laser’s repeatability, we conclude there was no change in optical alignment.

Figure 3. Comparison of wavelength pixel positions before and after the vibration test

In summary, we performed vibration testing to verify the s-Nova-1550 spectrometer’s durability against vibration. By comparing roll-off measurements and pixel positions of five wavelength signals before and after the test, we confirmed that the spectrometer’s alignment was not affected. Under typical vibration conditions that may occur between shipment and installation at customer sites, the spectrometer’s durability is sufficient and the measurement data can be considered reliable..