Recently, there has been a significant increase in demand for various smart devices such as smartphones, laptops, tablets, and car navigation systems. On the display screens of these devices, the protective films are commonly utilized to ensure durability and improve visibility. In particular, the three-layer structure of PET-adhesive-PET protective films is highly utilized due to its characteristics of high transmittance, scratch resistance, and excellent adhesion. To meet the performance requirements of these protective films, it is crucial to maintain thickness uniformity within a certain level based on the designed thickness values of both the PET and adhesive layers. Additionally, since PET's thickness is controlled by the stretch ratio during the manufacturing process, the refractive index varies with thickness. In cases of non-uniform stretching, significant differences in refractive index can occur depending on the polarization direction due to birefringence characteristics, making it necessary to know the refractive index information of PET in its final manufactured state [1].

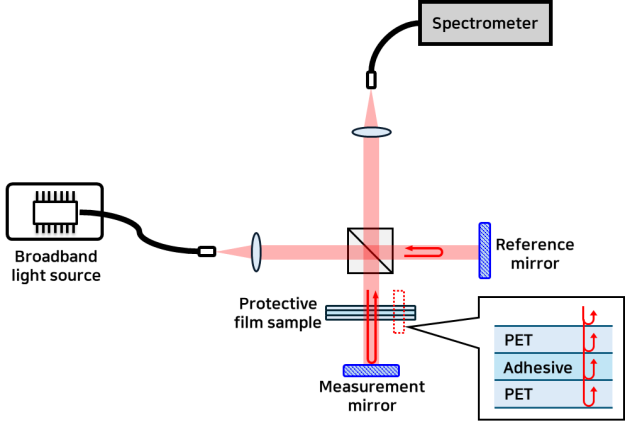

In this study, we propose a spectral interference method to measure the thickness and refractive index of each layer in the PET-adhesive-PET three-layer protective film structure [2-4], as shown in Fig. 1. The proposed method can independently measure the refractive index information of PET and the adhesive layer through separation of the protective film sample's layers, and use this information to obtain thickness data for each layer in the three-layer protective film structure. Measurements were performed on two types of protective films with different adhesive layer thicknesses, confirming successful measurement of thickness and refractive index in each sample. Furthermore, by rotating the sample relative to the optical axis and performing measurements in multiple directions, we confirmed differences in refractive index due to PET's birefringence characteristics. Consequently, polarization-based analysis of birefringence characteristics is required to improve the reliability of thickness measurement results. We expect that this measurement technology can be utilized to enhance inspection efficiency of protective films, which play an important role in improving the performance and lifespan of displays.

Fig. 1. Optical configuration of the proposed measurement system